Industries

Personal Care

High-quality raw materials and active ingredients for the Personal and Home Care industries.

Home Care and I&I

We specialise in raw materials for washing detergent and cleaning products and provide green, efficient solutions.

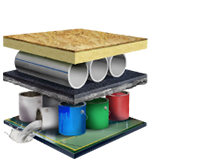

Performance Chemicals

Raw materials and additives that optimize processes and products both functionally and financially.

Industries

Personal Care

High-quality raw materials and active ingredients for the Personal and Home Care industries.

Home Care and I&I

We specialise in raw materials for washing detergent and cleaning products and provide green, efficient solutions.

Performance Chemicals

Raw materials and additives that optimize processes and products both functionally and financially.